Building better and faster? Product configuration is the way

And it is our speciality

We help you execute your product configuration projects from start to finish.

We use our Configuratori Project Management Methodology, which ensures your projects are delivered on time, on budget, and on scope

We create customized software projects with a variety of programming languages that can be used on PC, tablet and mobile starting from project specifications.

Whether technical programs, integrations between different systems, integration with calculation systems and CAD, business productivity improves, paying off the investment in a few months.

CAD Automation

Adapting products to customer specifications takes time and resources, slowing down all production processes. Automating the generation of CAD models is the most effective way to overcome these problems.

Increase the performance of your CAD

Our automations work with different platforms (SolidWorks, Inventor, SolidEdge) for the automatic generation of drawings and files

CAD design automation generates 3D models and drawings accurately and quickly for all company departments, from the engineering department to the sales team, respecting product specifications and reducing design errors.

Automatic BOM and Documents Generation

Generating workflow-related documents quickly and automatically results in increased profits and increased efficiency throughout the entire production cycle

Every product configuration received will be correct because it is strictly controlled by the rules set.

This means that only valid configurations pass through sales and engineering to the production team.

Bills of materials and all product-related documentation can be automatically generated based on the configuration, ensuring a smooth workflow from order to build phase.

Woodworking tools

The tools for wood can be considered an assembled, it must be chosen and sized according to the profile to be made taking into account the technological parameters to ensure greater productivity, but also trying to use standard parts.

Modeling custom parts with a 3D CAD system takes a long time.

In this case, a software has been developed which, starting from the technical needs of the user, after the sale, the project is developed automatically with enormous time savings, obtaining the 3D model and 2D drawing

Photovoltaic Simulator

We have developed some technical and financial simulators for the calculation of investments for photovoltaic systems.

Starting from the data on irradiation, our simulators calculate the energy produced by installed power, the number of panels required and the analysis of investments.

When connected to CRM, PDM and ERP (such as SAP, for example), they can automatically manage customer data, propose the optimum revenue generating solution, and automatically prepare any offer with all the attached documentation.

Pressurization and pumping systems

The pressurization systems require a choice, balancing and optimization of the components to meet the customer’s needs.

Whether an offer or the calculation following a sale, there is the need to calculate the main pump, the pilot pump, the evaluation of system costs, the choice between possible technical and economic alternatives.

This process is supported by an application developed specifically to support custom proposer configurations.

Configuratori has created the SellPumps software platform, adaptable to all company situations, for the configuration, design and generation of offers for pumping and pressurization systems.

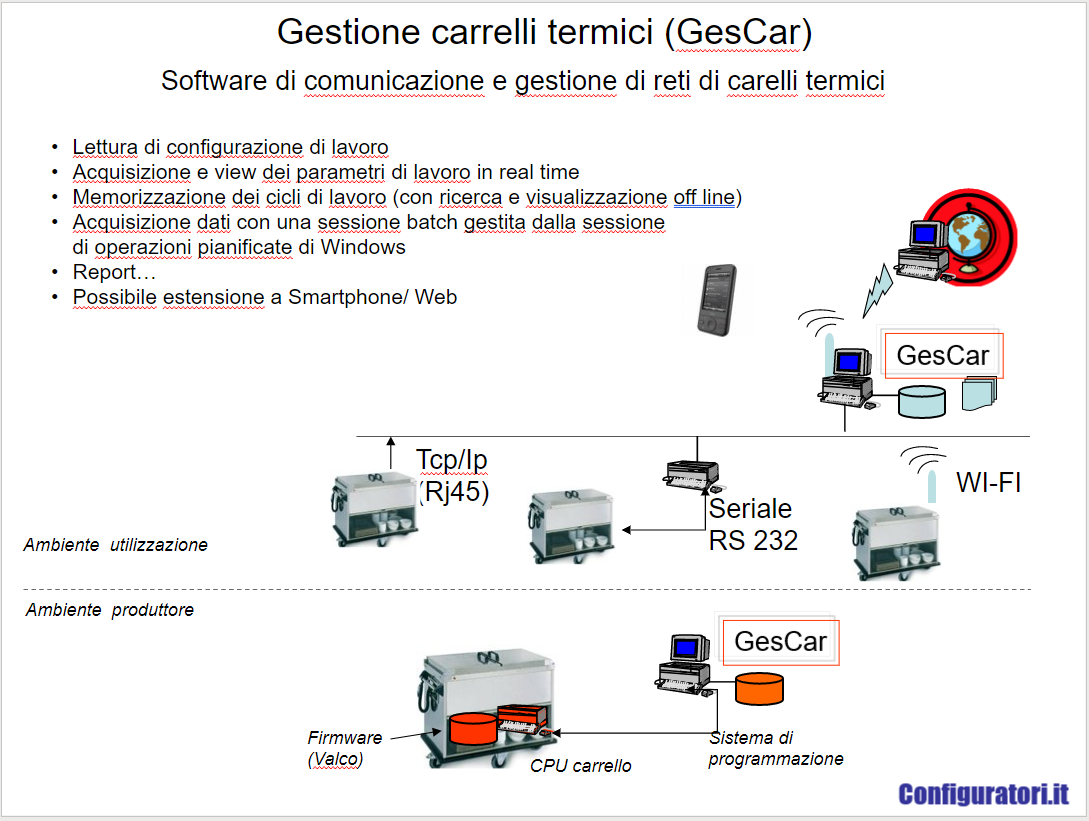

Thermal trolleys for hospitals

Electric trolleys need to be managed in a monitoring system and have a working configuration, which must be known and tracked.

For this, the work parameters are acquired in real time, the work cycles are stored (with search and offline display), acquiring the data with batch sessions managed by the Windows scheduled operations session and / or by a batch session.

Monitoring via Smartphone / Web and the use of RFID for localization identification possible.

Panel Cutting and Sheet Goods Optimization

To contain material costs, an automatic statistical optimization procedure has been developed which, starting directly from the 3D modeled CAD project, creates the structures to be built and directly generates the “band” layout for the numerical control.